-

Feeling isolated? You're not alone.

Join 20,000+ people who understand exactly how your day went. Whether you're newly diagnosed, self-identified, or supporting someone you love – this is a space where you don't have to explain yourself.

Join the Conversation → It's free, anonymous, and supportive.

As a member, you'll get:

- A community that actually gets it – no judgment, no explanations needed

- Private forums for sensitive topics (hidden from search engines)

- Real-time chat with others who share your experiences

- Your own blog to document your journey

You've found your people. Create your free account

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fred R Clark & Son Machineworks

- Thread starter Nitro

- Start date

Have you remembered to use your Gargoyle Mobil Oil? lol

I wonder if Mobil gas stations were originally called Gargoyle.

This is all very interesting. I like old farm equipment. And your tiny house looks amazing.

Well we folks over here in the States got to chalk another Independence Day into the books.

Yep, my Fourth of July was spent with my toys, #1 on the list was finishing up more repairs on the old Farmall.

A short while back I decided that it was time to change the exhaust/intake manifold on the engine.

Easy enough, grab the wrenches and get started.

Hole that brought about the repair

Yep, my Fourth of July was spent with my toys, #1 on the list was finishing up more repairs on the old Farmall.

A short while back I decided that it was time to change the exhaust/intake manifold on the engine.

Easy enough, grab the wrenches and get started.

Hole that brought about the repair

Not so fast Nitro, now she no longer wants to idle slow enough.

Easy enough, open up the governor assembly and rework it's adjustment.

Nope, not that easy.

More issues found inside.

The flyweights were striking the return spring

Simply adding a new spring wasn't the answer either

Crappy repair, blue

Extreme shaft, yellow

Worn and missing needle bearings, blue

Shaft wear, yellow

That ain't gonna fly, go look for new parts.

Nope, nothing available.

Easy enough, open up the governor assembly and rework it's adjustment.

Nope, not that easy.

More issues found inside.

The flyweights were striking the return spring

Simply adding a new spring wasn't the answer either

Crappy repair, blue

Extreme shaft, yellow

Worn and missing needle bearings, blue

Shaft wear, yellow

That ain't gonna fly, go look for new parts.

Nope, nothing available.

Wow, we used an old farm all and a john deere back in the 80s. They were antique then! I can only imagine the amount of upkeep to keep this in running condition.

Next up was the sloppy throttle actuating shaft:

Nope, almost ready to break after 74 years of operation.

Can't have that part fail, get busy.

Reform a replacement end?

Nope, too ugly.

Hmmm.

Wonder if there is room for a heim joint?

Yepperz.

Will need to use a small lathe that I don't have here.

Ok, accept defeat?

Na, use your head for something besides a place to hold a hat.

Adapt and conquer.

Nope, almost ready to break after 74 years of operation.

Can't have that part fail, get busy.

Reform a replacement end?

Nope, too ugly.

Hmmm.

Wonder if there is room for a heim joint?

Yepperz.

Will need to use a small lathe that I don't have here.

Ok, accept defeat?

Na, use your head for something besides a place to hold a hat.

Adapt and conquer.

No problem when you learn to adapt to your surrounding while expecting the unexpected.

Simply take the prop off yer old Evinrude outboard motor and mount her up to the 540 RPM PTO shaft.

Done deal

You put an outboard motor propeller on the tractor? That's outstanding.  I wonder how many knots a Farmall can do on the open seas.

I wonder how many knots a Farmall can do on the open seas.

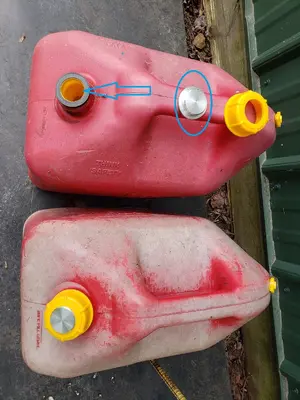

OK. Now this is something I can relate to. The other stuff is impressive, but I don’t know what most of it is.Last on the recent list was upgrades to two of my gasoline cans:

Replacement spouts and added vents.

The metal parts were machined so the cans can be transported with the pour nozzles inside while preventing spills.View attachment 132006

View attachment 132007

But I have plastic gas cans that look a lot like what you are displaying. I must have a dozen gas cans (all different models) and as far as I can tell there is something wrong with all of them.

It didn’t occur to me I could maybe fix them.

prolly a hunnert and plentyYou put an outboard motor propeller on the tractor? That's outstanding.I wonder how many knots a Farmall can do on the open seas.

I must have a dozen gas cans (all different models) and as far as I can tell there is something wrong with all of them.

Science still has not solved the gas can problem, I don't think I have ever had a gas can that wasn't a piece of crap.

Science still has not solved the gas can problem, I don't think I have ever had a gas can that wasn't a piece of crap.

Recently bought a not POC can but there are no longer sources for the replacement caps.

Simple enough, machine one complete out of ultra high molecular weight polyethylene using an original steel one as the pattern.

Two pass single pointed threaded the bores with a 2-1/2- 6 thread per inch thread.

The cap is back bored to accept a cork gasket.

Turned a $2.00 purchase into a very valuable item just by using a few skillsets.

(it pays to have the equipment needed as well)

Last edited:

So, that’s a metal gas can? And you made a new cap for it. Was the gas can a $2 purchase or the lid part. I understand the lid you custom tooled to fit this can. I do respect your ability to fix things.View attachment 132030

Recently bought a not POC can but there are no longer sources for the replacement caps.

Simple enough, machine one complete out of ultra high molecular weight polyethylene using an original steel one as the pattern.

Two pass single pointed threaded the bores with a 2-1/2- 6 thread per inch thread.

The cap is back bored to accept a cork gasket.

Turned a $2.00 purchase into a very valuable item just by using a few skillsets.

(it pays to have the equipment needed as well)

View attachment 132031

Yes, the metal can is a galvanized steel Eagle from years on back before safety regulations decided that gas cans had to be made from crap that doesn't hold up and leaks more fuel that seems to me to be very unsafe.So, that’s a metal gas can? And you made a new cap for it. Was the gas can a $2 purchase or the lid part. I understand the lid you custom tooled to fit this can. I do respect your ability to fix things.

The lid was made because I wasn't about to fork over $30 for a rusty old used one.

Not a single source could be found for a commercially made replacement, and trust me, with a background in manufacturing, I do know how to find stuff of that nature.

Part of my life's work was spend doing mechanical engineering and I was raised in a machineshop setting, so to me my fix was a no-brainer.

The plastic is forgiving enough to allow a decent thread fit to the rolled thread on the can and the cork gasket serves to seal it tight to the bung.

The plastic was a drop from a commercial project where we were making poly pulleys for wire accumulator equipment for a wire manufacturing company.

There were several rows of 18 inch pulleys that were mounted on fixed locations at the top of the frames and an opposite set mounted on slides that were designed to "accumulate" wire so that spool changes could be made during a run without shutting down the entire process.

The wire was payed off of the huge wooden reels then rewound on the smaller ones for resale.

The drops were from where we routed out the lightening holes in the pulleys.

We literally still have thousands of them.

There were several rows of 18 inch pulleys that were mounted on fixed locations at the top of the frames and an opposite set mounted on slides that were designed to "accumulate" wire so that spool changes could be made during a run without shutting down the entire process.

The wire was payed off of the huge wooden reels then rewound on the smaller ones for resale.

The drops were from where we routed out the lightening holes in the pulleys.

We literally still have thousands of them.

Share:

New Threads

-

-

Eric Bristow, Piers Morgan & Susanna Reid

- Started by Aspergers_Aspie

- Replies: 5

-

My boyfriend is threatening to dump me because of me getting medical guardianship. Is that reasonable?

- Started by dancerxoxo123

- Replies: 62

-

How I Was Treated Like Absolute Trash for Being an Autistic Person

- Started by marrowbuster

- Replies: 9

-

-

-

-

-

You ever impulsively post something really dumb, and regret it a minute later?

- Started by Yeshuasdaughter

- Replies: 19

-